Wastewater treatment plant sludge recovery system

Based on patent – P202030006 granted on 20-10-2020

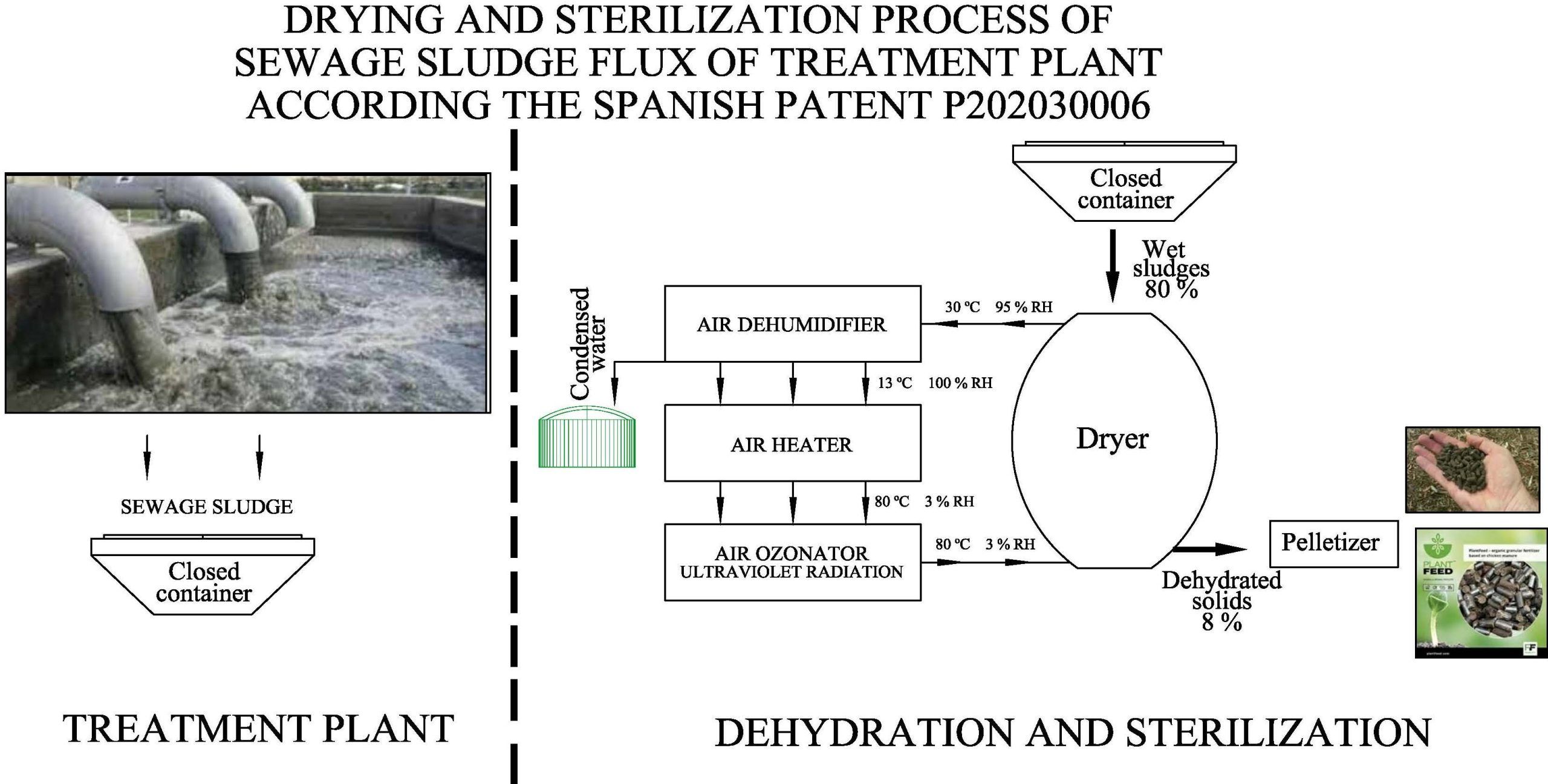

System for the valorisation by dehydration of organic waste or malodorous products, without the emission of odours, vapours or greenhouse gases.

Sources of wastewater:

- Domestic: Urban and rural dwellings

- Hotels and residences

- Social centres

- Recreational centres

- Hospitals

- Livestock

- Agricultural

- Industrial

all purification activities are based on:

- the separation of the water for its use and

- the elimination of the solid part by biological reactions and filtrations.

The waste from the purification process is called sludge

Study area – initial zoning

The study area is identified with the municipalities of: LA OLIVA, Puerto del Rosario, ANTIGUA, BETANCURIA, TUINEJE and PÁJARA.

TREATMENT CAPACITY

LA OLIVA 6.505,50 m3/day

Puerto del Rosario 5.326,00 m3/day

ANTIGUA 5.400,00 m3/day

BETANCURIA 115,00 m3/day

TUINEJE 3.185,00 m3/day

PÁJARA 18.678,00 m3/day

TOTAL CAPACITY 39.209,50 m3/day

sludge from selected areas:

|

MUNICIPIO LA OLIVA Puerto del Rosario ANTIGUA BETANCURIA TUINEJE PÁJARA TOTAL CAPACITY |

Sludge production 952 m3/year 778 m3/year 789 m3/year 12 m3/year 461 m3/year 2.729 m3/year 5.721 m3/year |

Sludge production 2,61 m3/day 2,13 m3/day 2,16 m3/day 0,03 m3/day 1,26 m3/day 7,48 m3/day 15,67 m3/day |

Current situation of the treatment of sewage sludge:

- Damage to fish fauna and eutrophication.

- Pollution of spring water and wells

- Environmental pollution due to stinking smells

- Bad image of the activity

- Bad image of the promoters

- Possible risks of spreading diseases and pests

- Loss of nutrients through degradation

- Emission of Greenhouse Gases, GHG, CH4, CO2, NH3 etc.

Future situation of sewage sludge treatment:

- Improvement of sewage treatment conditions

- Production of clean water for crops and nature

- Elimination of ponds and emissions of stinking odours

- Elimination of pathogenic micro-organisms

- Preservation of beneficial insects and worms

- No consumption of fossil fuels

- Elimination of GHG greenhouse gases

- Recovery of water from dehydration

- Manufacture of sterilised organic fertilisers

- Manufacture of patented hydrogen ways2h.com/

- Job creation

production of sewage sludge from the island of Fuerteventura:

Total sludge production of the island 5.721 m3/year

Surface of the island 1.660 km2

Population 119.732 inhabitants

Inhabitant per tourism approx. 12 %.

Annual incidence per inhabitant 0,65 m3/inhabitant

Incidence on the surface 3,45 m3/km2

Sludge composition

Water 80%

Solids 20%

Sewage sludge movement system:

Sludge is loaded into trucks to transport chain containers daily by dumping from the sludge separation systems.

Truck transporting "chain containers".

Chain container with top closure for sludge draining with 80 % moisture content.

Dewatering and conditioning

Sludge will be received, analysed, sorted and treated in treatment plants strategically located to minimise transport.

Sewage sludge with 80 % moisture.

INLET

- Sludge tank

- Dewatering machinery

Sludge input 5.721 m3/year – 15,67 m3/day

ENERGY

- Photovoltaic panels

- Wind turbines

OUTPUT

- Dewatered sludge storage

- Reclaimed water storage

Fertiliser output 1.430,25 t/year – 0,163 t/hour

Reclaimed water output 4.290.75 m3/year- 0,49 m3/hour

Reclaimed water storage tanks

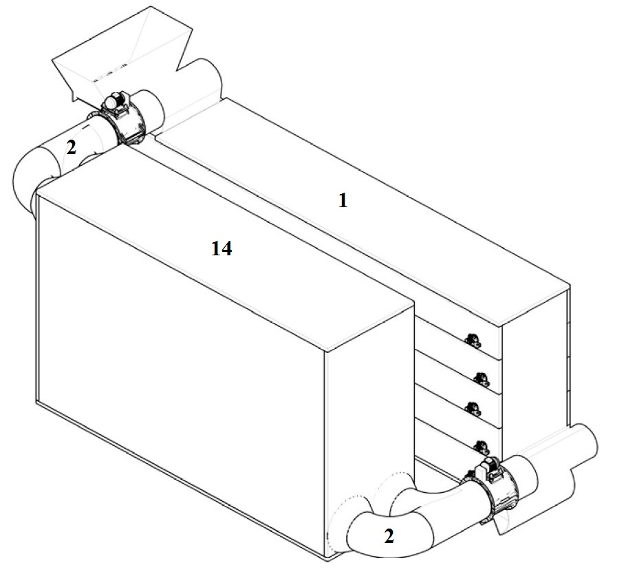

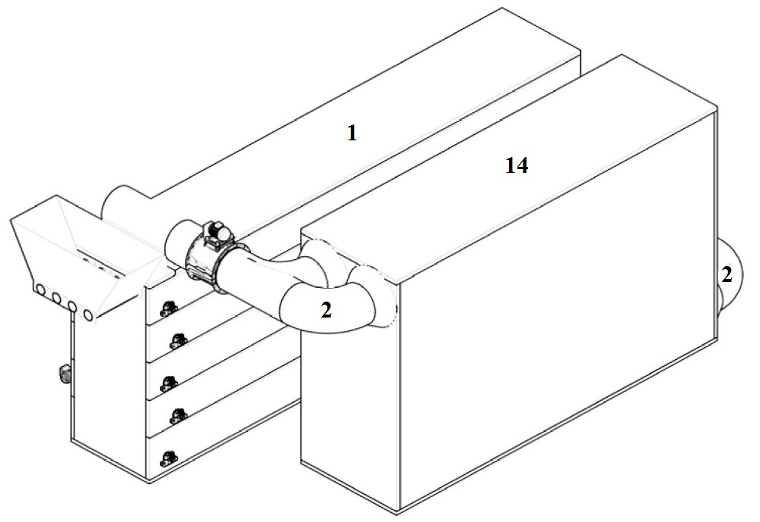

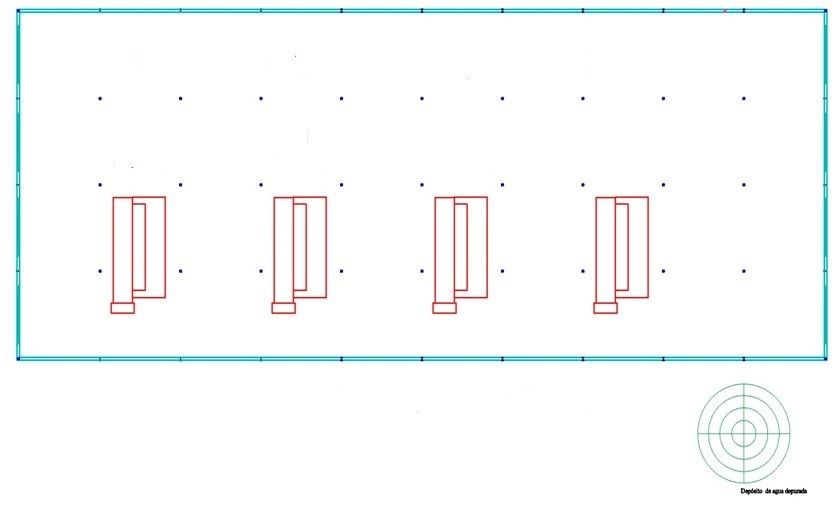

Sludge dehydrator

Patented machines are used to dehydrate the solid part of the sludge with 80 % humidity and to obtain sterilised dehydrated solid fertiliser with 20 % humidity, working in a closed circuit.

Sewage sludge recovery type plant

Sewage sludge to be recovered 5.720 ton/year

Production of recovered sludge 1.430 ton/year

Recovered water production 4.290 m3/year

Our Headquarters

Landline Telephone: +34 881 934 772

WhatsApp Mobile Phone: +34 659 547 415 & +34 633 032 526

Email: mposada@sewagesludge.es

Address: Avda. Eduardo Pondal, 19, 2º, D

15110 Ponteceso

A Coruña

Spain